GOLD PURITY CHECKING INSTRUMENTS

X-RAY FLUORESCENCE SPECTROMETERS GAS PROPORTIONAL XRF DETECTOR CGX-101 Manufacturer Supplier and Exporters

XRF is used to detect and analyze noble metals like Gold ( Au), Silver (Ag), Platinum (Pt),Iridium (Ir), Osmium (Os), Palladium (Pd), Rhodium (Rh), Ruthenium (Ru), Copper (Cu), Zinc (Zn), Nickel (Ni), Cadmium (Cd), Iron (Fe), Cobalt (Co), Indium (In), Tin (Sn), in the Jewellery Industry.

Energy Dispersive X-ray Fluorescence (EDXRF) technique relies on the detector and the detection circuit capability to resolve spectral peaks due to different energy X-Rays emitted when a primary X-Ray beam strikes a metal alloy corresponding to different elements in the sample, intensity of the spectrum radiation proportional to the concentration of element. The spectrum is then processed through the powerful computer software which calculates and reports the various elements & their composition in the sample.

XRF Gold Purity Tester consists of X-Ray tube, high voltage power supply for X-Ray source, X-Ray tube filters, X-Ray fluorescence Detector, processing electronics and system interface & an external computer. A camera is incorporated in the system to view the sample on the computer screen.

Specifications:

* Detectable elements : Iron (Fe), Cobalt (Co), Nickel (Ni), Copper (Cu), Zinc (Zn),

Ruthenium (Ru), Rhodium (Rh), Palladium (Pd), :

Silver (Ag), Cadmium( Cd), Indium (In), Tin (Sn),

Osmium (Os), Iridium (Ir), Platinum (Pt), Gold (Au)

* Measurement Results : Cu (Combined with Fe, Co, Ni, Zn)

Ag (Combined with Ru, Rh, Pd, Cd, In, Sn)

Au (Combined with Os, Ir, Pt)

* Accuracy of measurement : ±0.3% (Molten Metal above 90% Au)

±0.5% (Molten Metal below 90% Au) :

±1% (Molten Metal below 50% Au)

* Sensor : Gas Proportional Counter

* Cooling for Detector : Air

* Detection Range : 1%-----99.99%

* Testing Time : 30-----200 secs

* Test Spot Area : 0.3mm

* Power Supply : 200-240V AC, 50/60Hz

* Power Rating : 130 Watt

* Working Temperature : 15-25°C

* Relative humidity : <70%

* Operation atmosphere : Vibration free surface and air conditioned room

* Interface for Computer : Inbuilt (External Monitor, Keyboard required)

* Software for Operation : Menu Driven User Friendly Operating System

* Dimensions of Instrument : Length : 450mm Width : 350mm

Height : 345mm (with test compartment cover in : closed

position) & 565mm (in open position)

* Dimensions of Sample Chamber : Length : 300mm Width : 255mm Height : 80mm

* Net Weight : 30kg

XRF is a reference technique, hence standards are required for quantitative results. Standards are analyzed, spectral intensities generated are used to obtain a intensity v/s concentration plot for calibration. This calibration is used to evaluate the spectral intensities of unknown samples.

How to get best results from XRF Spectrometer :

XRF is a reference method, proper standardization of the equipment is required for accurate results.

In order to get most appropriate results, testing at different points is necessary especially when the jewellery design is intricate.

Adequate warm up period, sturdy working surface, stable power supply, proper grounding and conditioned atmosphere is required to achieve the best product performance.

For powder sample, proper grinding of sample minimizes scattering effect.

For solid sample, surface polishing minimizes the scattering effect.

Flat surface of the sample yields the best results.

Due to different melting points, atomic structure and crafting techniques, not all the elements can be melted with noble metals.

X-RAY FLUORESCENCE SPECTROMETERS SILICON - PIN XRF DETECTOR CGX-102 Manufacturer Supplier and Exporters

XRF is used to detect and analyze noble metals like Gold ( Au), Silver (Ag), Platinum (Pt), Iridium (Ir), Osmium (Os), Palladium (Pd), Rhodium (Rh), Ruthenium (Ru), Copper (Cu), Zinc (Zn), Nickel (Ni), Cadmium (Cd), Iron (Fe), Cobalt (Co), Indium (In), Tin (Sn), in the Jewellery Industry.

Energy Dispersive X-ray Fluorescence (EDXRF) technique relies on the detector and the detection circuit capability to resolve spectral peaks due to different energy X-Rays emitted when a primary X-Ray beam strikes a metal alloy corresponding to different elements in the sample, intensity of the spectrum radiation proportional to the concentration of element. The spectrum is then processed through the powerful computer software which calculates and reports the various elements & their composition in the sample.

XRF Gold Purity Tester consists of X-Ray tube, high voltage power supply for X-Ray source, X-Ray tube filters, X-Ray fluorescence Detector, processing electronics and system interface & an external computer. A camera is incorporated in the system to view the sample on the computer screen.

Specifications:

* Detectable elements : Titanium to Uranium

* Measurement Results : Iron (Fe), Cobalt (Co), Nickel (Ni), Copper (Cu), Zinc (Zn),

Ruthenium (Ru), Rhodium (Rh), Palladium (Pd),

Silver (Ag), Cadmium( Cd), Indium (In), Tin (Sn),

Osmium (Os), Iridium (Ir), Platinum (Pt), Gold (Au)

-all metals separately.

* Accuracy of measurement : ±0.15% (Molten Metal above 90% Au)

±0.3% (Molten Metal below 90% Au)

±0.5% (Molten Metal below 50% Au)

* Sensor : Silicon-Pin Diode (Silicon Drift Semiconductor or CGX-103)

* Cooling for Detector : Thermoelectric

* Detection Range : 1%-----99.99%

* Testing Time : 30-----200 secs

* Test Spot Area : 0.5mm

* Power Supply : 90-240 V AC, 50/60HZ

* Power Rating : 30 Watt

* Working Temperature : 15-25°C

* Relative humidity : <70%

* Operation atmosphere : Vibration free surface and air conditioned room

* Interface for Computer : Inbuilt (External Monitor, Keyboard required)

* Software for Operation : Menu Driven User Friendly Operating System

* Dimensions of Instrument : Length : 335mm Width : 225mm

Height : 210mm (with test compartment cover in : closed

position) & 565mm (in open position)

* Dimensions of Sample Chamber : Length : 235mm Width : 195mm Height : 80mm

* Net Weight : 12kg

XRF is a reference technique, hence standards are required for quantitative results. Standards are analyzed, spectral intensities generated are used to obtain a intensity v/s concentration plot for calibration. This calibration is used to evaluate the spectral intensities of unknown samples.

How to get best results from XRF Spectrometer :

XRF is a reference method, proper standardization of the equipment is required for accurate results.

In order to get most appropriate results, testing at different points is necessary especially when the jewellery design is intricate.

Adequate warm up period, sturdy working surface, stable power supply, proper grounding and conditioned atmosphere is required to achieve the best product performance.

For powder sample, proper grinding of sample minimizes scattering effect.

For solid sample, surface polishing minimizes the scattering effect.

Flat surface of the sample yields the best results.

Due to different melting points, atomic structure and crafting techniques, not all the elements can be melted with noble metals.

SILICON DRIFT DETECTORS CGX-103

SDD in place of Si-Pin Detector for enhanced performance & Detection (Spectral Resolution)

Specifications

* Detectable elements : Titanium to Uranium

* Measurement Results : Iron (Fe), Cobalt (Co), Nickel (Ni), Copper (Cu), Zinc (Zn),

Ruthenium (Ru), Rhodium (Rh), Palladium (Pd),

Silver (Ag), Cadmium( Cd), Indium (In), Tin (Sn),

Osmium (Os), Iridium (Ir), Platinum (Pt), Gold (Au)

-all metals separately.

* Accuracy of measurement : The Accuracy of measurement is better than

Silicon-pin Detector

* Sensor : Silicon Drift Detector is used in the place of Silicon-Pincode

Detector for Enhanced performance & spectral resolutions.

* Cooling for Detector : Thermoelectric

* Detection Range : 1%-----99.99%

* Testing Time : 30-----200 secs.

* Test Spot Area : 0.5mm

* Power Supply : 90-240 V AC, 50/60HZ

* Power Rating : 30 Watt

* Working Temperature : 15-25°C

* Relative humidity : <70%

* Operation atmosphere : Vibration free surface and air conditioned room

* Interface for Computer : Inbuilt (External computer required)

* Software for Operation : Menu Driven User Friendly Operating System

* Dimensions of Instrument : Length : 335mm Width : 225mm

Height : 210mm (with test compartment cover in : closed

position) & 330mm (in open position)

* Dimensions of Sample Chamber : Length : 235mm Width : 195mm Height : 80mm

* Net Weight : 12kg

X-RAY FLUORESCENCE SPECTROMETER HANDHELD DETECTORS (Si-PIN / SDD) CGX-104

XRF is used to detect and analyze noble metals like Gold ( Au), Silver (Ag), Platinum (Pt),Iridium (Ir), Osmium (Os), Palladium (Pd), Rhodium (Rh), Ruthenium (Ru), Copper (Cu), Zinc (Zn), Nickel (Ni), Cadmium (Cd), Iron (Fe), Cobalt (Co), Indium (In), Tin (Sn), in the Jewellery Industry.

Energy Dispersive X-ray Fluorescence (EDXRF) technique relies on the detector and the detection circuit capability to resolve spectral peaks due to different energy X-Rays emitted when a primary X-Ray beam strikes a metal alloy corresponding to different elements in the sample, intensity of the spectrum radiation proportional to the concentration of element. The spectrum is then processed through the powerful computer software which calculates and reports the various elements & their composition in the sample.

XRF Gold Purity Tester consists of X-Ray tube, high voltage power supply for X-Ray source,X-Ray tube filters, X-Ray fluorescence Detector, processing electronics and system interface& an external computer. A camera is incorporated in the system to view the sample on the computer screen.

Specifications:

| X-ray tube | Tungsten anode, 40 kV , 100 µA with 5 filter positions |

| Detector type | solid state Si-pin-diode with thermo-electrical cooling (optional SDD) |

| Active area | 6 mm2 |

| Energy resolution | <165 eV at 5.9 keV (<140 eV for SDD) |

| Display | High resolution 4 inch color touch-screen |

| Supported operating systems |

Windows CE/Mobile for PDA Windows XP/Vista/7 for PC |

Battery Operation Time : Up to 8 hours

Dimensions : 242 mm (L) x 78 mm (W) x 230 mm (H)

Weight (with battery) : 1230 g (1440 g)

XRF is a reference technique, hence standards are required for quantitative results. Standards are analyzed, spectral intensities generated are used to obtain a intensity v/s concentration plot for calibration. This calibration is used to evaluate the spectral intensities of unknown samples.

How to get best results from XRF Spectrometer :

XRF is a reference method, proper standardization of the equipment is required for accurate results.

In order to get most appropriate results, testing at different points is necessary especially when the jewellery design is intricate.

Adequate warm up period, sturdy working surface, stable power supply, proper grounding and conditioned atmosphere is required to achieve the best product performance.

For powder sample, proper grinding of sample minimizes scattering effect.

For solid sample, surface polishing minimizes the scattering effect.

Flat surface of the sample yields the best results.

Due to different melting points, atomic structure and crafting techniques, not all the elements can be melted with noble metals.

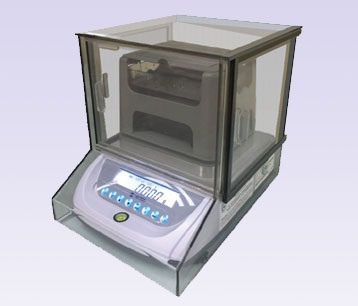

Manufacturer,Supplier,Exporter of GOLD PURITY CHECKING BALANCE

* Measurement based on Archimedes' principle incorporating High Precision electronic weighing scale.

* Accurate, Reliable and non destructive testing method.

* Provision to enter water temperature for temperature compensation of

density value.

* Over load and shock load protection for weighing scale.

* Display of gold purity in % as well as karat.

* Gold purity checking in gold-copper-silver, gold-silver, gold-copper alloys.

* Can be used to check other precious metals like platinum, palladium etc.

by using mixture proportion function.

* RS-232 interface for printer / computer connection.

* Spacious tank for big ornaments, special design of tank to reduce buoyancy error.

* Hollow ornaments, ornaments inlaid with stones cannot be checked.

Specifications:

| Models | CAH-323 | CAH-603 |

| Capacity | 320g | 600g |

| Accuracy | 0.001g | 0.001g |

| Density Accuracy | 0.01 g/cc | 0.01 g/cc |